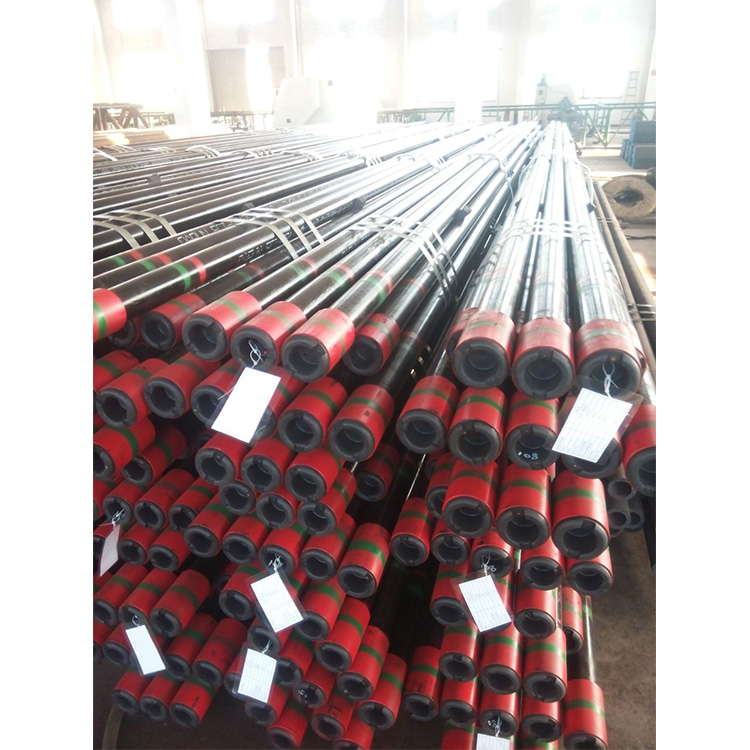

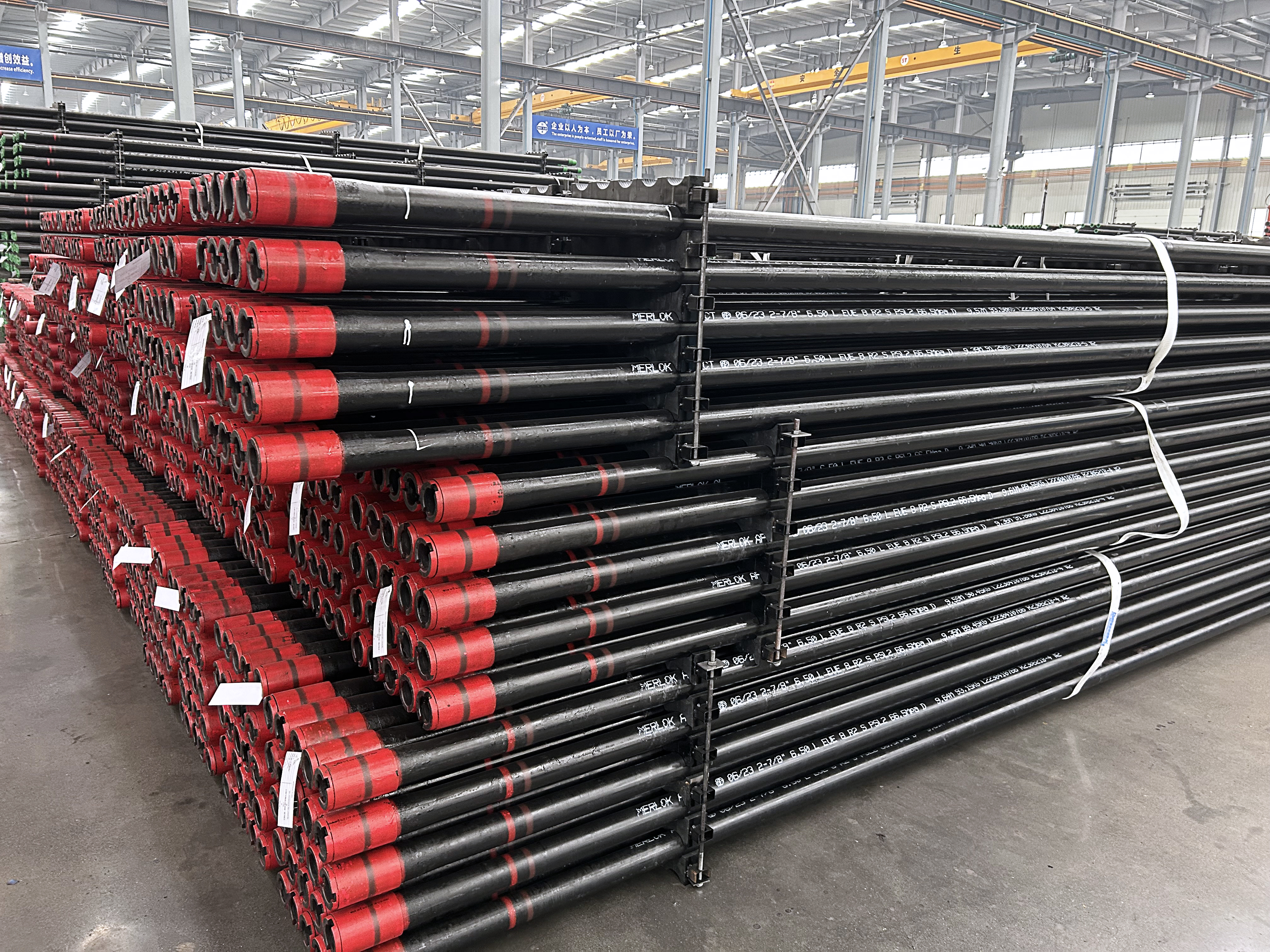

Nace MR0175 Tubing And Casing

I. Anti-H2S corrosion tubing and casing

APPLICABLE STANDARDS

API SPEC 5CT Specification for casing and Tubing.

ANSI/NACE MR0175 Metals sulfide stress cracking and stress corrosion resistance in sour oilfield environment.

ANSI/NACE TM0177 Laboratory testing of metals for resistance to sulfide stress cracking and stress corrosion cracking in H2S environment.

ISO 15156 Petroleum and natural gas industries-material for use in H2S containing environments in oil and gas production.

ISO 13680 Petroleum and natural gas industries corrosion-resistant seamless tubes for use as casing , tubing and coupling stock technical delivery conditions third edition.

I. Anti-H2S corrosion tubing and casing

APPLICABLE STANDARDS

API SPEC 5CT Specification for casing and Tubing.

ANSI/NACE MR0175 Metals sulfide stress cracking and stress corrosion resistance in sour oilfield environment.

ANSI/NACE TM0177 Laboratory testing of metals for resistance to sulfide stress cracking and stress corrosion cracking in H2S environment.

ISO 15156 Petroleum and natural gas industries-material for use in H2S containing environments in oil and gas production.

ISO 13680 Petroleum and natural gas industries corrosion-resistant seamless tubes for use as casing , tubing and coupling stock technical delivery conditions third edition.

Mechanical Property

Grade | Product Name | Yield strength(MPa) | Tensile Strength(Mpa) | Elogation | Charpy V-impact/J | Max. Hardness/(HRC) | |

Min | Max | Min | |||||

80 | BL80S | 552 | 655 | 655 | Calculated according to API 5CT formula | According to API 5ct | 80 |

BL80SS | |||||||

90 | BL90S | 621 | 724 | 689 | 90 | ||

BL90SS | |||||||

95 | BL95S | 655 | 758 | 724 | 95 | ||

BL95SS | |||||||

110 | BL110S | 758 | 862 | 793 | 110 | ||

BL110S | |||||||

Corrosion Resistance

Product Name | Requirements of anti- corrosion Nature | |

H2S Stress Corrosion Cracking Test (SSC) | ||

Solution A according to NACE TM 0177 A, without crack after 720 Hours | ||

Ø6.35/Sample | Ø3.81/Sample | |

Loading SMYS value | ||

BL80S, BL90S, BL95S | 85% | 76% |

BL80SS, BL90SS, BL 95SS | 90% | 80% |

BL110S | 80% | 72% |

BL110SS | 85% | 76% |

Note: Sulfur resistance grade ‘S” Reefers to normal sulfur resistance; “SS” indicates high sulfur resistance